Deserts are overflowing with sand. The land that dies for lack of water has an infinite supply of sand. So why not use that sand to build dams that store water?

It doesn’t work. Desert sand is too fine and round — water can’t flow through it. You just end up with a giant mud pit. To build a sand dam that traps water within sand, you need to haul in river sand from far away. Over 60% of the construction cost goes to transporting sand. The places dying for lack of water can’t afford to buy sand either.

If we could use the free desert sand lying around everywhere, costs would drop to one-fifth. Is that possible?

Turning Useless Sand into Engineered Coarse Aggregate

I’ve devised a forming technique that makes desert sand as coarse and solid as river sand. It’s called Oasis Pellet. Here’s the recipe:

- Desert sand — 95%

- Lignin — a byproduct discarded by paper mills. It’s the natural binding agent in wood.

- Citric acid — a food additive found in oranges and lemons. It acts as a hardener.

- Solar heat — baked under the intense desert sun. No fossil fuels required.

Mix these ingredients and form them into pellets 5–10 mm in diameter, and you get engineered coarse aggregate that lets water flow freely through it.

Every ingredient is food-safe, making it safe for use in drinking water sources. Cross-linked with citric acid, the pellets acquire the properties of a natural plastic that doesn’t dissolve in water. No 700°C kiln, no complex chemical processes. Just mix, shape, and dry under the desert sun.

Three-Layer Hybrid Structure

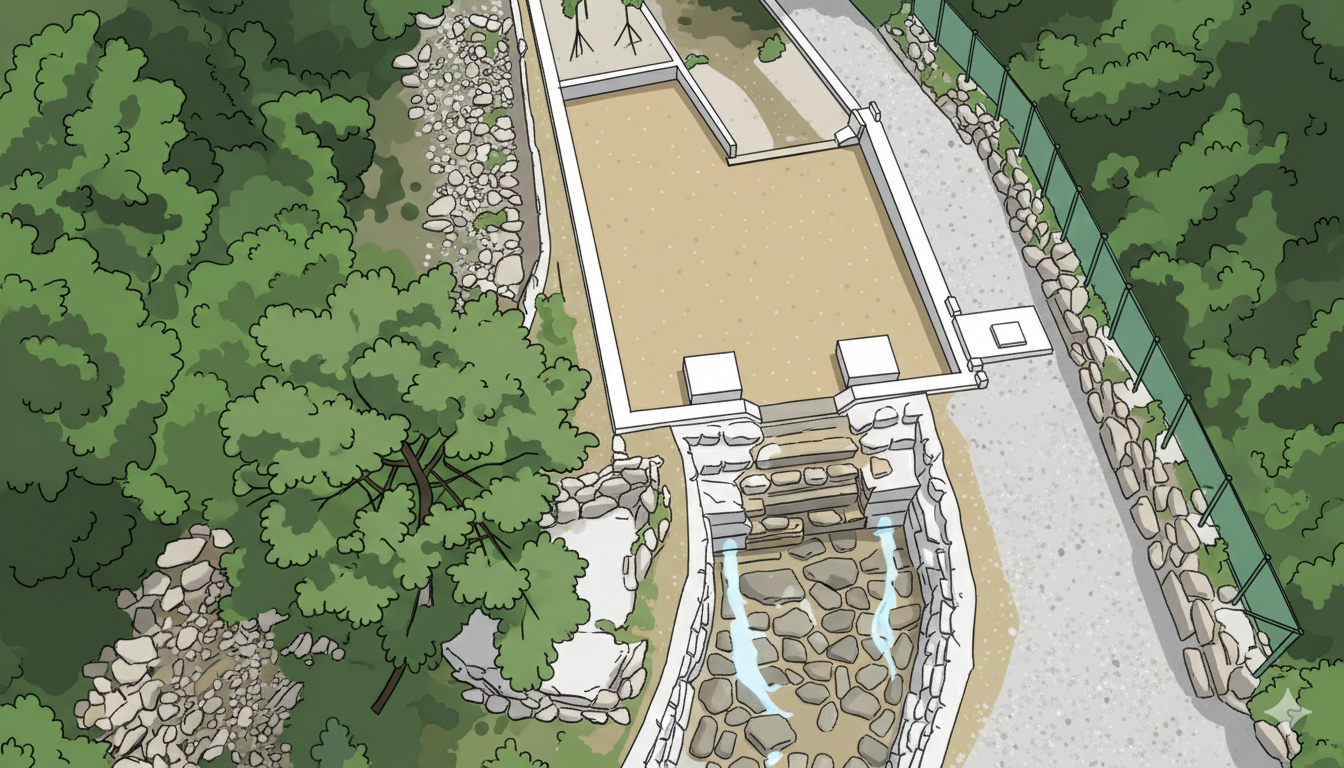

It’s not just about filling a dam with pellets. To achieve both structural stability and cost efficiency, the dam is built in three layers.

Layer 1: Base — Not a Single Drop Leaks

Desert sand is mixed with lime and pozzolan — an adaptation of ancient Roman concrete. A hydraulic reaction that grows stronger underwater creates a perfect waterproof seal. This serves as both the foundation and the bottom liner of the dam.

Layer 2: Core (90%) — A Massive Clean Water Tank

Oasis Pellets make up 90% of the total volume. Clean water is stored in the wide voids between the coarse pellets.

The key is the anaerobic environment sealed above and below. When oxygen is cut off, microorganisms cannot break down the lignin. The pellets last for decades without decomposing.

Layer 3: Top Cap (10%) — The Oxygen Barrier

This is the only material sourced externally. A 30–50 cm layer of river sand and gravel covers the top. It serves three purposes:

- Oxygen barrier — prevents decay of the pellet layer below.

- Ballast — keeps the lighter pellets from washing away during floods.

- Filter — provides a first line of defense against external contaminants.

Over 90% of all materials are sourced locally. Expensive external sand is needed only for the 10% cap. With the same budget, you can build five times as many dams.

30 Years Later, the Dam Becomes a Forest

The real twist of this technology comes after its useful life ends.

Oasis Pellets have a lifespan of roughly 20–30 years. When the dam is decommissioned, the lignin pellets gradually decompose into humus. Desert sand transforms into fertile soil where plants can grow.

Worthless desert sand becomes a water tank, and the water tank becomes forest soil. Industrial waste (lignin) meets desert sand to create life-giving water, and in the end, it all returns as forest — a complete cycle.

Where Can This Be Used?

Africa, the Middle East, Mongolia. It can be applied to ODA projects in arid climate regions. Mobile equipment — just a few truckloads — goes to the site and builds local dams with local sand. The desert provides the energy.

| Conventional Sand Dam | Oasis Pellet | |

|---|---|---|

| Sand sourcing | 100% remote river sand | 90% local desert sand |

| Transport cost share | Over 60% | Under 10% |

| Estimated cost | Baseline | 60–70% reduction |

| Energy | Heavy machinery | Solar drying |

| After end of life | Sand debris | Fertile soil |

The technology is simple. The materials are already on-site. All that’s needed is the first dam to prove it works.